PHDSOFT JOINS INTERNATIONAL CONSORTIUM OF DIGITAL TWINS

Global engineering and technology company, PhDsoft has been a member of the Digital Twin Consortium since last year, an international membership organization working to advance the use of digital twins across industries. It is a global consortium…

PHDSOFT IS FINALIST AT THE ZURICH INNOVATION CHAMPIONSHIP 2022

Global Engineering & Technology, PhDsoft is finalist at the Zurich Innovation Championship 2022, one of the leading international innovation competitions in the insurance industry. Sponsored by global insurance company Zurich, the award…

TAKING FLIGHT ON ANOTHER WORLD: DIGITAL TWINS ON MARS

A year ago, on July 30, 2020, NASA launched Perseverance rover to continue studying signs of life on Mars. The equipment was sent aboard the Atlas-V rocket. Inside the rover, the Mars helicopter, Ingenuity, a technology demonstration to test…

PORT OF HOUSTON WILL USE C4D, PHDSOFT DIGITAL TWIN

One of the world's largest ports and one of the most efficient container ports in North America, the Port of Houston will use PhDsoft's C4D digital twin to improve operational performance, reduce inspection and maintenance costs, and maximize…

C4D, FROM PHDSOFT, IS A CASE OF BRAZILIAN SUCCESS

In 2012, TN Petroleo magazine, one of the leading publications in Brazil's oil and gas sector, highlighted the launch of a new version of C4D, PhDsoft's digital twin.

"Unique in the world, [C4D] is used to maintain the integrity of offshore…

DIGITAL TWINS: PROTAGONISTS OF TECHNOLOGICAL TRANSFORMATION

An article published in January in the MIT Technology Review - Massachusetts Institute of Technology magazine - points out that digital twins are the protagonists of the technological transformation underway.

According to Guga Stocco, creator…

DIGITAL TWINS: STRATEGIC TECHNOLOGY FOR THE PRESENT AND THE FUTURE

One of the pillars of the so-called Industry 4.0, digital twins are considered by the global consultancy Gartner one of the ten most relevant trends in the IT field.

According to the consultancy, a third of global organizations will adopt artificial…

PHDSOFT PARTNERSHIP WITH SIEMENS FEATURED ON SIEMENS’ MINDSPHERE WEBSITE

In recognition of PhDsoft’s readiness to enable the digital transformation of the maintenance process of structures, static equipment and piping, PhDsoft is now highlighted on Siemens’ mindsphere.io website in the Featured Partners page.

C4D…

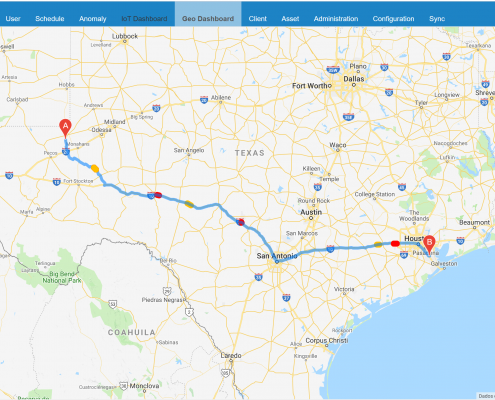

Digital Transformation for pipelines, railways and roads.

Partners and customers understanding the benefits of our Smart Digital Twin approach asked for a solution for pipelines, railways, and roads. The answer is the Geo Dashboard where risks are showed in color. Every variable such as pressure, temperature,…

PhDsoft will have global presence by the end of 2019

Did you know that, beyond USA and Brazil, PhDsoft is already in Italy, China and Singapoor, that will serve as a base for all Asia operations? Behind this growth is PhDsoft’s COO, Rosana Ellis. Based in Houston, she has been commanding the…